Views: 0 Author: Site Editor Publish Time: 2025-08-22 Origin: Site

You will find that Microfluidizer technology stands out as the better choice for most lab high shear homogenizer applications in 2025. Its chamber design delivers smaller droplets and a narrower size distribution in a single pass, which improves sample preparation efficiency and consistency. When you select equipment, you need to consider several key factors:

The type of sample preparation, especially if you work with soft or tough tissues.

Desired droplet size and stability for your lab high shear homogenizer process.

Application requirements, such as nanoemulsion or pharmaceutical formulations.

Manufacturer support throughout research and development.

Expect a detailed comparison that will help you select the best option for your needs.

Microfluidizer technology delivers smaller, more uniform particles with higher consistency, making it ideal for precise lab applications like pharmaceuticals and nanomaterials.

High pressure homogenizers handle larger volumes faster and suit robust samples, but may produce less uniform particle sizes and require more maintenance.

Microfluidizers use less energy and fewer passes to achieve target particle sizes, saving time and reducing sample waste in sensitive workflows.

Choosing the right homogenizer depends on your sample type, desired particle size, batch size, budget, and ease of use needs.

Microfluidizer systems offer user-friendly operation with simple cleaning and quick training, while high pressure homogenizers need more hands-on maintenance and monitoring.

You need to understand the main differences between Microfluidizer and high pressure homogenizer technologies before choosing a lab high shear homogenizer. The table below compares these two options with other leading high-shear homogenizers and inline homogenizers:

Brand/Model | Core Mechanism | Pressure Range | Particle Size Control | Throughput | Typical Applications |

|---|---|---|---|---|---|

Microfluidizer | Microchannel, fixed-geometry chamber | Up to 30,000 psi | Precise, uniform, nano | Low to medium | Pharma, biotech, nanomaterials |

High Pressure Homogenizer | Piston-driven valve, turbulence/cavitation | 8,000-40,000 psi | Less precise, wider range | High | Food, beverage, cell disruption |

Silverson | Rotor stator homogenizer | Low to medium | Moderate, batch | Medium | Food, cosmetics, emulsions |

VEVOR | High shear mixer homogenizer | Low to medium | Moderate | Medium | Lab, pilot, chemical |

PRO Scientific | Rotor stator homogenizer | Low to medium | Moderate | Medium | Life sciences, tissue processing |

Dosimix | Inline homogenizer | Medium | Moderate | High | Industrial, continuous processing |

ShearJet | Counter jet valve | Medium | Precise, uniform | Low to medium | Nanomaterials, research |

SCILOGEX | High shear batch mixers | Low to medium | Moderate | Medium | Lab, pharma, food |

Labtron | High shear batch mixers | Low to medium | Moderate | Medium | Lab, pharma, food |

Chemspeed | Inline homogenizer | Medium | Moderate | High | Automated R&D, process development |

OMNI | Rotor stator homogenizer | Low to medium | Moderate | Medium | Biotech, pharma, food |

Tip: Microfluidizer and high pressure homogenizer systems both use high-shear technology, but their mechanisms and results differ significantly. Microfluidizer devices use microchannels to create uniform, high-frequency shearing, while high pressure homogenizers rely on turbulence and cavitation from a piston-driven valve.

You can choose from several types of lab high shear homogenizer, each with a unique mechanism. Microfluidizer systems use a fixed-geometry chamber and constant pressure to deliver consistent, repeatable results. High pressure homogenizers use a piston pump and valve to generate turbulence and cavitation, but pressure fluctuations can lead to less uniform particle sizes. Rotor stator homogenizer and high shear mixer homogenizer models, such as those from Silverson or OMNI, use mechanical tearing and shear from rotating elements. Inline homogenizers and high shear batch mixers offer continuous or batch processing for various sample types.

When you select a homogenization system, consider the core technology. Microfluidizer devices excel at producing smaller, more uniform particles, especially for heat-sensitive or delicate samples. High pressure homogenizers work well for robust samples and high-throughput needs. Inline homogenizers and high shear batch mixers provide flexibility for continuous or batch workflows. High-shear homogenizers, including rotor stator homogenizer and high shear mixer homogenizer models, remain popular for their versatility and ease of use in many lab settings.

You need precise control over particle size when you work with a Lab high shear homogenizer. Microfluidizer systems and high pressure homogenizers both produce nanoparticles in the sub-100 nm range, which is essential for pharmaceutical and cosmetic sample preparation. For example, nanostructured lipid carriers made with high pressure homogenization often reach particle sizes around 230 nm, while ultra-small carriers can measure about 80 nm. Microfluidizer devices use parallel microchannels to optimize shear rates, resulting in smaller and more uniform particles in a single pass. This high-shear technology is especially valuable when you require tight droplet size distribution for advanced formulations.

Tip: Smaller particle sizes improve delivery and stability in nanoemulsions and suspensions. You should always check the specifications of your Lab high shear homogenizer to ensure it meets your sample preparation goals.

You want reliable sample consistency and stability for every batch. Microfluidizer processors force samples through narrow microchannels at high velocity, generating intense shear forces that break down particles into highly uniform sizes. This process creates homogeneous mixtures, which are critical for accurate analysis and reproducible results. High pressure homogenizers also reduce particle size and improve homogeneity, as seen in Coenzyme Q10 nanoliposome studies where particle size dropped from 143 nm to 97 nm and PDI values fell below 0.3. These improvements lead to stable dispersions and better retention rates, with treated samples maintaining about 95% stability after 20 days at 4 °C.

Microfluidizer systems offer precise control and reproducibility, especially for small sample volumes.

High pressure homogenizers achieve quantifiable improvements in particle size distribution and long-term stability.

Both technologies disrupt vesicle aggregation and reorganize lipid bilayers, supporting enhanced physical stability.

You should select a Lab high shear homogenizer that matches your sample preparation needs, especially if you work with precious or limited samples. Devices like rotor stator homogenizer and high shear mixer homogenizer models provide versatility, but Microfluidizer systems deliver superior sample consistency for demanding applications.

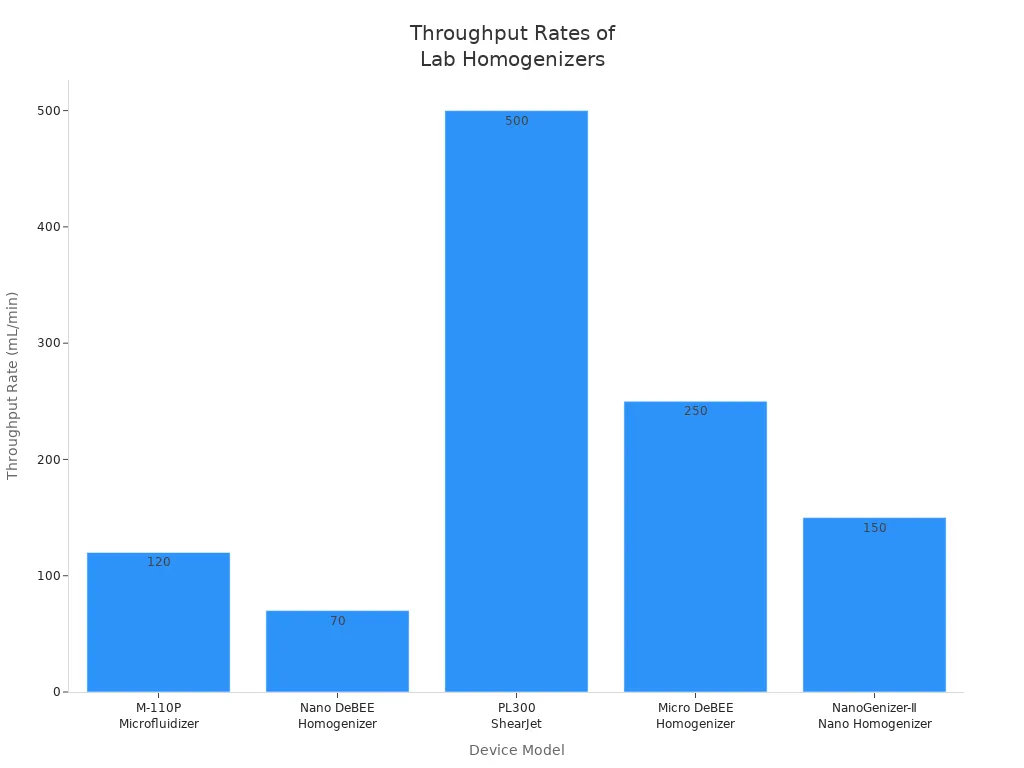

Throughput determines how quickly you can process samples in your laboratory. Microfluidizer and high pressure homogenizer models offer a range of throughput rates to fit different workflows. The table below compares several popular devices:

Device Model | Throughput Rate (mL/min) | Minimum Sample Size (mL) |

|---|---|---|

Microfluidics M-110P Microfluidizer | Up to 120 | 50 |

LM20 Microfluidizer® Processor | N/A | 14 |

Nano DeBEE High Pressure Homogenizer | Up to 70 | N/A |

PL300 ShearJet® High-Pressure Homogenizer | Up to 500 | N/A |

Micro DeBEE High Pressure Homogenizer | Up to 250 | N/A |

NanoGenizer-Ⅱ Nano High Pressure Homogenizer | 60 to 150 | 5 |

You can process larger volumes faster with high pressure homogenizers like the PL300 ShearJet, which reaches up to 500 mL/min. Microfluidizer models such as the M-110P handle up to 120 mL/min, making them suitable for small to medium batch sample preparation. Rotor stator homogenizer and high shear mixer homogenizer devices also support medium throughput, which works well for routine lab tasks. When you choose a Lab high shear homogenizer, consider your required throughput and minimum sample size to optimize your workflow and maintain sample consistency.

You often need precise control over particle size and consistency in pharmaceutical sample preparation. Microfluidizer technology stands out in this field because it produces extremely small and uniform particles, which are essential for drug delivery systems. Regulatory agencies require strict adherence to cGMP standards. Microfluidizer processors meet these requirements and are widely used in FDA-approved drug manufacturing. High pressure homogenizers offer scalability for large-scale production, but you may find their particle size control less precise.

Feature/Aspect | Microfluidizer | High Pressure Homogenizer |

|---|---|---|

Operating Pressure | 5,000 to 30,000 psi | Few hundred to several thousand psi |

Particle Size Reduction | Smaller, more uniform particles | Less fine particle size |

Consistency of Output | High consistency | Requires more monitoring |

Typical Scale of Use | Small-scale, precise formulation | Larger scale production |

Common Applications | Drug development, life sciences research | Emulsification, cell disruption |

Cost and Maintenance | Higher cost and maintenance | Lower cost, more operator input |

Why Preferred in Pharma | Critical for drug delivery and formulation | Preferred for scalability and cost |

Note: You should select a Microfluidizer for pharmaceutical sample preparation when you need high consistency and regulatory compliance.

You rely on Lab high shear homogenizer systems for efficient cell disruption, protein extraction, and liposome formation. Both Microfluidizer and high pressure homogenizer devices minimize heat buildup, which protects sensitive proteins from denaturation. You can process a wide range of cell types, including bacterial, mammalian, and plant cells. This versatility supports applications in vaccines, gene therapy, and drug discovery.

You preserve sample integrity due to minimal heat generation.

You achieve scalability from small experiments to large production without sacrificing quality.

You benefit from efficient mixing and stable emulsions, which are vital for reproducible results.

You may also use rotor stator homogenizer and high shear mixer homogenizer models for routine sample preparation tasks, especially when you need flexibility and ease of use.

You improve product quality and shelf life in food and beverage processing by using high pressure homogenizers and Microfluidizer systems. High pressure homogenizers excel at producing uniform textures in dairy and sauces, preventing separation and enhancing stability. Microfluidizer technology achieves even smaller particle sizes and narrower distributions, which boosts consistency and bioavailability in high-value products.

Technology | Operating Pressure Range | Key Applications | Impact on Product Quality |

|---|---|---|---|

High Pressure Homogenizer | 500 psi to 20,000 psi | Dairy, sauces | Uniform texture, prevents separation, improves stability |

Microfluidizer | Up to 30,000 psi | Nanoemulsions, encapsulation | Smaller particles, better consistency, higher bioavailability |

You should consider Microfluidizer systems for high-performance emulsifying solutions in food innovation, especially when you need advanced encapsulation or nanoemulsion capabilities.

You create stable nanoemulsions and encapsulate hydrophobic compounds using both Microfluidizer and high pressure homogenizer technologies. Microfluidizer devices, especially dual-channel models, allow you to process oil and water phases separately, enabling one-step nanoemulsion production with high oil loading. You achieve smaller droplet sizes and narrower distributions, which are critical for nanomaterial stability.

Aspect | Microfluidizer (Single-Channel) | Microfluidizer (Dual-Channel) | High-Pressure Homogenizer |

|---|---|---|---|

Application | Two-step nanoemulsion | One-step nanoemulsion | Flexible, multi-pass |

Droplet Size and Distribution | Small, uniform | Smaller, more uniform | Larger, less uniform |

Processing Efficiency | Multiple passes, some waste | Single pass, less waste | Multiple passes needed |

Oil Loading Capacity | Lower (~10%) | Higher (up to 50%) | Moderate |

You can use these emulsification and homogenization solutions for pharmaceuticals, food, and personal care products. Microfluidizer systems often deliver the most stable nanomaterial emulsions, making them a top choice for advanced sample preparation.

You want to maximize homogenization efficiency in your laboratory workflow. The choice of homogenization techniques directly impacts how quickly and uniformly you process samples. Microfluidizer processors and high pressure homogenizers both deliver high shear, but their designs lead to different outcomes.

Parameter | Microfluidizer Processor | High Pressure Homogenizer (HPH) |

|---|---|---|

Number of Passes | 2 passes | 5 passes |

Operating Pressure | 10,000 psi | 30,000 psi |

Particle Size Achieved | ~180 nm droplet size | ~180 nm droplet size (after more passes) |

Power Consumption | Lower (7.5 times less than HPH) | Higher power consumption |

Efficiency and Uniformity | Faster particle size reduction, better uniformity | Slower reduction, less uniform particles |

You achieve target particle sizes with fewer passes using a Microfluidizer processor. This means you spend less time and energy on each batch. High pressure homogenizers require more passes and higher pressure, which increases power consumption and processing time. If you use a Lab high shear homogenizer for nanoemulsion or pharmaceutical applications, you benefit from the Microfluidizer’s ability to deliver consistent results quickly.

Tip: You can further optimize the homogenization process by selecting the right device for your sample type. For routine tasks, rotor stator homogenizer and high shear mixer homogenizer models offer reliable performance, but Microfluidizer systems excel when you need rapid, uniform particle reduction.

You should consider throughput and sample size requirements. Microfluidizer processors handle small to medium batches efficiently, while high pressure homogenizers suit larger volumes but may sacrifice speed and uniformity. When you compare homogenization efficiency, Microfluidizer technology stands out for its ability to reduce particles faster and with less energy.

You need reproducible results in every experiment. Consistency in the homogenization process ensures that your data remains reliable and your formulations meet quality standards. Microfluidizer technology provides superior reproducibility by maintaining constant pressure and using a fixed-geometry chamber. Every portion of your sample receives identical treatment, which leads to tighter particle size distributions and more uniform nanoemulsions.

High pressure homogenizers, while effective, face challenges that can affect repeatability. Valve wear, cooling requirements, and cleaning procedures introduce variability. These factors can impact the consistency of your results, especially in repeated laboratory experiments. Microfluidizer processors generate less heat, which helps preserve the physiochemical properties of sensitive materials. You achieve seamless scalability and repeatability, making Microfluidizer systems the preferred choice for demanding applications.

You maintain batch-to-batch consistency with Microfluidizer processors.

You minimize variability in particle size and sample quality.

You support regulatory compliance and reliable data generation.

Note: If you use a Lab high shear homogenizer for critical research or production, reproducibility becomes essential. Rotor stator homogenizer and high shear mixer homogenizer models provide good repeatability for routine tasks, but Microfluidizer systems deliver unmatched consistency for advanced formulations.

You should evaluate your workflow and sample requirements before selecting a homogenization process. Microfluidizer technology offers the best balance of efficiency and reproducibility, especially for applications that demand precise control and uniformity.

When you consider a Lab high shear homogenizer for your laboratory, you need to evaluate the initial investment carefully. The price range for these systems varies widely based on technology, capacity, and features. Here is what you can expect:

High pressure homogenizers typically require an initial investment between $50,000 and $500,000. The cost depends on the machine’s throughput, automation, and advanced features.

These systems involve complex engineering, which means you must plan for significant capital expenditure.

Microfluidizer systems usually come with a higher upfront cost than standard high pressure homogenizers. This premium reflects their ability to deliver consistent, high-quality results, especially for demanding applications.

If you want to manage your lab budget, you can consider purchasing used Microfluidizer equipment from reputable suppliers.

Tip: Always compare the total cost of ownership, not just the purchase price. Factor in the value of consistent results and reduced sample waste when you select a Lab high shear homogenizer.

You may also look at alternatives like a rotor stator homogenizer or a high shear mixer homogenizer. These options often have lower entry costs and can suit routine sample preparation, but they may not match the performance of Microfluidizer or high pressure homogenizer systems for advanced applications.

Ongoing maintenance plays a crucial role in the total cost of owning a Lab high shear homogenizer. You need to account for regular servicing, replacement parts, and skilled personnel to keep your equipment running efficiently.

High pressure homogenizers require frequent valve and seal replacements due to wear from high operating pressures.

Microfluidizer systems, while robust, also need routine maintenance to ensure the microchannels remain clean and unobstructed.

Both systems benefit from scheduled professional servicing, which helps prevent costly downtime.

A rotor stator homogenizer or high shear mixer homogenizer usually involves simpler maintenance routines. These devices have fewer moving parts and lower pressure operation, which can reduce service costs. However, you should always follow the manufacturer’s guidelines to maximize equipment lifespan and maintain sample quality.

You can extend the life of your Lab high shear homogenizer by training staff on proper operation and cleaning procedures. This approach minimizes unexpected repairs and supports consistent performance across all your laboratory workflows.

You want a Lab high shear homogenizer that makes your workflow smooth and efficient. Microfluidizer processors stand out for their user-friendly design. You can operate these systems with minimal training. Digital controls guide you through each step, reducing the risk of user error. Cleaning is straightforward. You do not need to disassemble complex parts or use special tools. This simplicity saves you time and helps you maintain consistent results.

High pressure homogenizers, on the other hand, often require more hands-on attention. You may need to manually disassemble valves for cleaning, which can be time-consuming and requires technical skill. Manual controls increase the chance of inconsistency between batches. You also need to monitor cooling closely to prevent overheating, especially when processing sensitive samples.

When you use a rotor stator homogenizer or a high shear mixer homogenizer, you benefit from easy setup and quick cleaning. However, you must remain cautious. Contact with moving parts can cause injury if you do not follow safety protocols. Noise levels can reach up to 85 dBA, so you should consider hearing protection in busy labs.

Tip: Choose a Lab high shear homogenizer with digital controls and clear safety features. This approach improves your experience and reduces operational risks.

You do not need specialized skills to operate most Microfluidizer processors. The intuitive interface and automated features make training quick and straightforward. New users can learn to run a Lab high shear homogenizer in a short time. Routine maintenance is simple, so you spend less time on upkeep and more time on research.

High pressure homogenizers demand more in-depth training. You must learn how to safely disassemble and reassemble valves. Proper cleaning techniques are essential to avoid contamination and equipment damage. Electrical hazards and noise exposure require additional safety instruction.

For rotor stator homogenizer and high shear mixer homogenizer models, you should focus on safe handling and proper shutdown procedures. Manual handling of the homogenizing head can lead to injury or machine malfunction if you skip steps. Always train your team on safety and maintenance to ensure reliable operation.

Remember: Consistent training keeps your Lab high shear homogenizer running smoothly and protects your team from accidents.

You gain several advantages when you choose a Microfluidizer as your Lab high shear homogenizer. This technology uses fixed-geometry Interaction Chambers™ to apply extreme shear rates under constant pressure. You achieve efficient and uniform cell disruption, which leads to higher product recovery and easier downstream processing. Here are the main pros and cons:

Provides consistent and gentle cell breakage, which helps you recover more proteins and enzymes from your samples.

Delivers nearly 100% protein and enzyme release in E. coli cells, making it ideal for sensitive biological applications.

Meets cGMP standards, so you can use it for pharmaceutical and regulated environments.

Offers simple, linear scalability from lab to production, which saves you time during scale-up.

Works across many cell types, including soft mammalian, bacterial, and yeast cells.

Outperforms traditional Lab high shear homogenizer methods, such as rotor stator homogenizer and high shear mixer homogenizer, in viscosity control, filtration, and particle size distribution.

Achieves higher rupture rates with less time and energy compared to other technologies.

Note: Microfluidizer systems do not process solid foods or large particles well. You also need a separate sterilization step, since mechanical force does not sterilize your samples. Some energy loss as heat can occur during emulsification or dispersion.

You benefit from high pressure homogenizer technology when you need a Lab high shear homogenizer for food, biotech, or environmental applications. This method uses intense pressure to rupture cells and mix samples. The table below summarizes the main pros and cons:

Aspect | Pros | Cons |

|---|---|---|

Performance | Effective for solubilizing sludge and increasing methane production. | Requires precise valve control for consistent results. |

Efficiency | Less energy intensive than some mechanical pretreatments. | High operational pressures and complexity can pose challenges. |

Versatility | Reduces odor and improves biogas production in digestion processes. | Can worsen sludge dewaterability in some combinations. |

Food Safety | Inactivates pathogens, extends shelf life, and preserves nutrients. | Does not sterilize; needs separate sterilization step. |

Applications | Suitable for pasteurization, sterilization, and cell disruption. | Not suitable for solid foods or large particles. |

You find high pressure homogenizers useful for a wide range of Lab high shear homogenizer tasks. However, you must monitor pressure and equipment closely. Like Microfluidizer and rotor stator homogenizer systems, high pressure homogenizers lose some energy as heat and require regular maintenance. For routine lab work, you may also consider a high shear mixer homogenizer for easier operation and lower maintenance.

You need a clear checklist to select the best Lab high shear homogenizer for your laboratory. Start by identifying your sample type and desired outcome. Use the table below to compare Microfluidizer, high pressure homogenizer, rotor stator homogenizer, and high shear mixer homogenizer options.

Criteria | Microfluidizer | High Pressure Homogenizer | Rotor Stator Homogenizer | High Shear Mixer Homogenizer |

|---|---|---|---|---|

Pressure Range | 5,000–30,000 psi | Hundreds–thousands psi | Low–medium | Low–medium |

Particle Size Reduction | Finest, most uniform | Effective, less fine | Moderate | Moderate |

Scale of Operation | Small-scale, precise | Large-scale, scalable | Batch, flexible | Batch, flexible |

Maintenance & Safety | Precise cleaning needed | More operator input | Simple maintenance | Simple maintenance |

Budget Considerations | Higher cost, lease options | Lower cost, flexible | Lowest cost | Lowest cost |

Common Applications | Pharma, biotech, nano | Food, dairy, cell disruption | Routine lab, emulsions | Routine lab, emulsions |

Tip: Leasing a Lab high shear homogenizer helps you avoid large upfront costs and supports rapid deployment. You can preserve your budget for research and staffing by choosing flexible financing.

Ask yourself these questions:

What is your sample type (biological, food, chemical, nanomaterial)?

Do you need extremely small, uniform particles or is moderate reduction sufficient?

Will you process small batches or scale up to larger production?

How much can you invest in equipment and maintenance?

Do you require advanced automation or simple manual operation?

You should review your workflow, sample requirements, and financial strategy before making a final decision. This approach ensures you select the Lab high shear homogenizer that matches your laboratory’s needs and supports consistent, high-quality results.

You will find Microfluidizer technology delivers superior performance for most Lab high shear homogenizer applications. The table below highlights why laboratory professionals prefer Microfluidizer over high pressure homogenizer for precise particle size, efficiency, and sample quality.

Feature | Microfluidizer | High Pressure Homogenizer |

|---|---|---|

Particle Size Control | More precise, uniform | Less precise |

Efficiency | Consistent, energy-saving | Effective for large volumes |

Suitability | Delicate, high-value | Robust, large-scale |

You may choose a high pressure homogenizer, rotor stator homogenizer, or high shear mixer homogenizer for large batches or routine tasks.

Review your decision guide.

Consult experts.

Explore used equipment and warranty options.

Consider your sample type, budget, and workflow before purchasing a Lab high shear homogenizer.

You achieve finer particle size and better sample uniformity with a Lab high shear homogenizer. Compared to a rotor stator homogenizer or a high shear mixer homogenizer, you get more consistent results, especially for nanoemulsions and pharmaceutical applications.

You can use a rotor stator homogenizer for basic mixing or emulsification. However, a Lab high shear homogenizer delivers smaller particle sizes and higher reproducibility. For advanced tasks, you should consider a high shear mixer homogenizer or a Microfluidizer.

You should follow the manufacturer’s cleaning protocol. Most Lab high shear homogenizer models, including rotor stator homogenizer and high shear mixer homogenizer types, require flushing with cleaning solution and disassembling key parts for thorough sanitation.

A high shear mixer homogenizer works for many samples, but you may see better results with a Lab high shear homogenizer. For delicate proteins or nanoemulsions, you should compare performance with a rotor stator homogenizer as well.

You must wear protective gear and follow all safety instructions. Both rotor stator homogenizer and high shear mixer homogenizer devices have moving parts. Always ensure the Lab high shear homogenizer is off before cleaning or maintenance.