Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

The role of homogenizers and high shear mixers is pivotal in industries that require precise particle dispersion and uniform consistency in products. Whether it’s for pharmaceutical emulsions, cosmetic creams, or food products, both tools are indispensable for ensuring that the end product meets quality standards. However, their mechanisms, capabilities, and efficiency differ, making it crucial to understand when and why one might be preferred over the other.

In this article, we will compare the two devices in terms of their working principles, speed and efficiency, applications, and the role of Lubricant Additive components in optimizing their performance.

Homogenizer:

A homogenizer is a device designed to break down large particles in a mixture into smaller ones, creating a uniform and stable dispersion system. It achieves this through high-pressure or high-shear force, typically using a rotor-stator setup. The key factor that distinguishes a homogenizer is its ability to achieve uniformity in particle size, which is vital when working with Lubricant Additive components. These additives, which are often used in lubricants to improve performance, must be evenly distributed within the base fluid for optimal effectiveness. A homogenizer ensures this distribution is achieved, particularly in formulations requiring fine emulsions or suspensions.

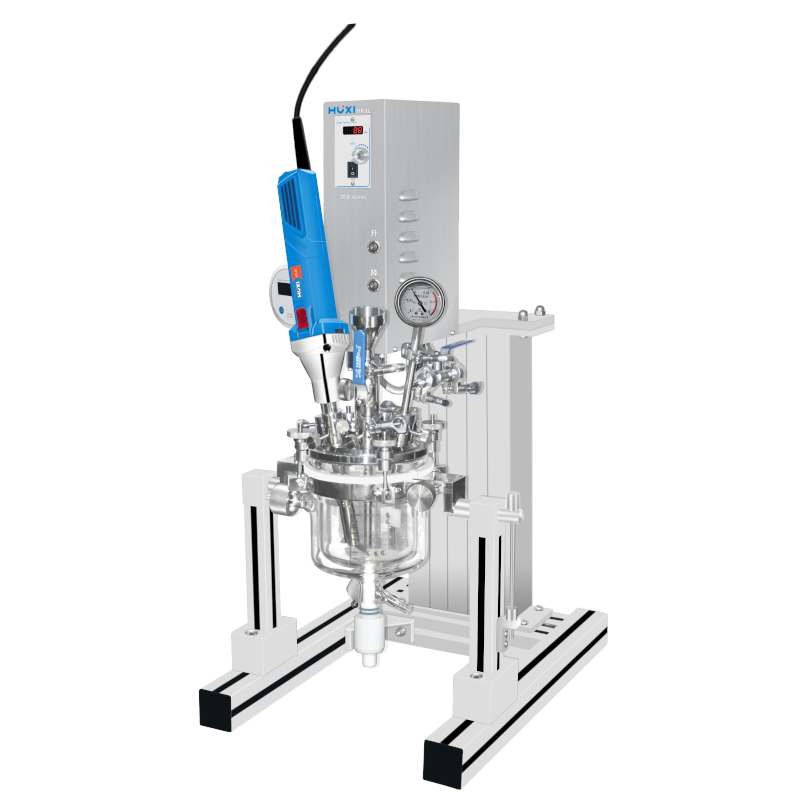

High Shear Mixer:

A high shear mixer, on the other hand, also works with high-speed rotation but is typically designed to blend or mix materials rather than breaking down particles. It uses high-speed shear forces to mix materials quickly and efficiently. The high shear mixer is ideal for applications that require rapid mixing and blending, such as when incorporating Lubricant Additive components into a base liquid. However, while it may achieve good homogeneity, it doesn’t necessarily reduce particle size or provide the same level of precision as a homogenizer.

Homogenizer:

Homogenizers are designed for precision, often operating at higher speeds to break down larger particles and achieve a finer, more uniform particle distribution. However, the increased speed and precision come with a trade-off. Homogenizers often have lower yield compared to mixers because they focus more on the quality of the mixture rather than the volume of production. This makes them ideal for smaller-scale operations or situations where consistency is the highest priority.

High Shear Mixer:

In contrast, high shear mixers operate at lower speeds but can handle larger volumes of material more efficiently. These mixers are ideal for bulk production where speed and volume are more important than precise particle size control. High shear mixers are often used in scenarios where high throughput is necessary, such as in the food and beverage industries, or in the mixing of Lubricant Additive components where dispersion is more critical than particle size reduction.

Homogenizer:

Homogenizers are commonly used in industries where particle size consistency is paramount. They excel in producing uniform emulsions, suspensions, and solutions. Some of the most common applications of homogenizers include:

Pharmaceuticals: Homogenizers are essential in the production of injectable medications and vaccines, where uniform particle sizes are necessary for effectiveness.

Lubricants: In the formulation of lubricants, Lubricant Additive components are often used to enhance viscosity, reduce wear, and improve performance. Homogenizers ensure these additives are evenly dispersed in the oil or grease base.

High Shear Mixer:

While high shear mixers may not offer the same level of particle size control, they are ideal for applications where rapid mixing is necessary. Common uses include:

Food and Beverage: High shear mixers are often used for blending liquids, creating stable emulsions (e.g., mayonnaise or salad dressings), and processing powders.

Chemicals: For the production of resins, coatings, adhesives, and other bulk materials where speed and efficiency are more important than fine particle control.

Whether a homogenizer or high shear mixer is better depends on the specific needs of the application. Homogenizers excel in applications requiring precise particle size reduction and uniformity, making them ideal for pharmaceuticals, cosmetics, and high-performance lubricants where Lubricant Additive components must be evenly distributed. High shear mixers, on the other hand, are ideal for bulk production, offering high efficiency and volume with moderate precision.