Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

In various industrial applications, especially in laboratories and production environments, two essential processes that are frequently used are homogenization and emulsification. Both serve to break down materials into smaller particles, but they achieve this goal through different methods and are used for distinct purposes. In this article, we will explore the key differences between these two processes, highlighting their applications, benefits, and the technology behind them.

Homogenization is a mechanical process used to reduce the size of particles in a substance, creating a uniform mixture. This process is commonly used in food processing, pharmaceuticals, and cosmetic industries. The goal of homogenization is to break down the particles into smaller sizes and ensure they remain uniformly distributed within the mixture.

Uniformity: The primary goal of homogenization is to create a uniform dispersion of particles in a liquid. This is crucial for products like milk, where fat globules need to be broken down and evenly distributed.

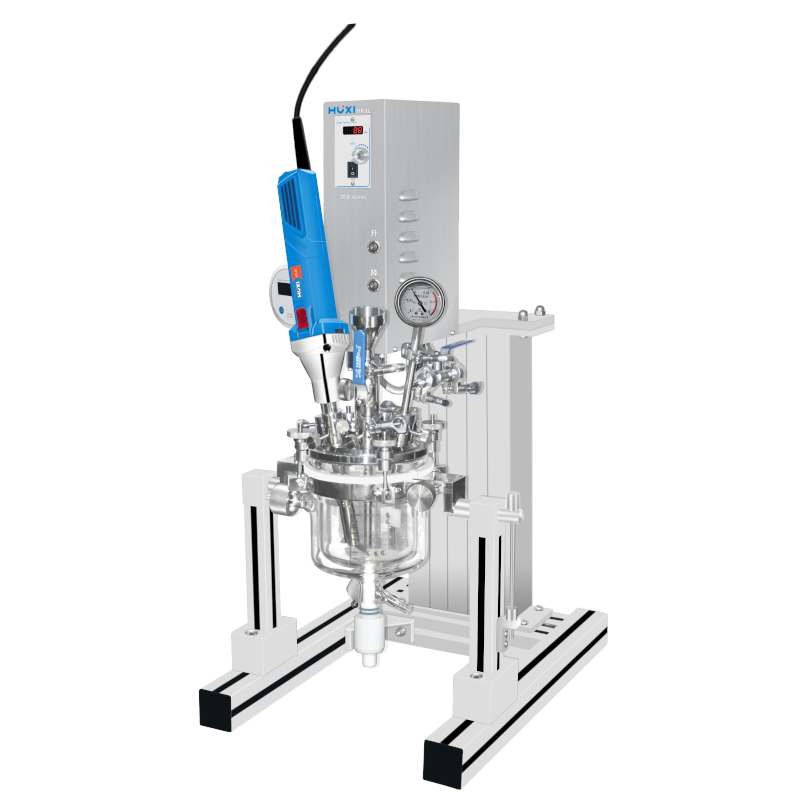

Process: Homogenization typically uses high pressure or high shear forces to break down particles. The equipment used for homogenization includes high-shear homogenizers and high-pressure homogenizers.

Applications: In food and beverage industries, homogenization is often used in milk, cream, sauces, and beverages. It is also crucial in pharmaceuticals and cosmetics for creating stable products with a consistent texture.

Emulsification is a process of mixing two immiscible liquids, typically oil and water, to form a stable mixture known as an emulsion. The process involves breaking down the oil into tiny droplets and dispersing them uniformly within the water phase. Unlike homogenization, which focuses on particle size reduction in a single phase, emulsification is specifically aimed at creating stable two-phase mixtures.

Two-Phase Mixture: The end result of emulsification is a stable mixture of two immiscible liquids, such as oil and water. This is important for applications where the ingredients need to be combined for stability and performance.

Process: Emulsification typically involves the use of an emulsifier, a substance that stabilizes the oil droplets within the water phase. High-shear mixing equipment or ultrasonic devices can also be used for emulsification.

Applications: Emulsification is used in the production of creams, lotions, ointments, sauces, and many food products. In the cosmetic industry, emulsification is key for creating lotions and emulsions, while in the food industry, it is essential for products like mayonnaise and salad dressings.

| Aspect | Homogenization | Emulsification |

|---|---|---|

| Goal | Create uniform particle size dispersion | Create stable mixtures of immiscible liquids |

| Process | Uses high pressure or shear forces to break down particles | Uses emulsifiers or high-shear mixing to combine immiscible liquids |

| Type of Mixture | Single-phase mixture (uniform liquid) | Two-phase mixture (e.g., oil and water) |

| Applications | Dairy products, pharmaceuticals, cosmetics | Sauces, dressings, lotions, ointments, and emulsions in food and cosmetics |

| Key Equipment | High-shear homogenizers, high-pressure homogenizers | Emulsifiers, high-shear mixers, ultrasonic devices |

The decision to use homogenization or emulsification depends largely on the type of product being manufactured and the desired properties of the end product.

Homogenization is preferred when a uniform dispersion of particles in a liquid is required. This process is most commonly used in dairy, beverage, and pharmaceutical industries, where the breakdown of particles (such as fat globules or other solid substances) is necessary for consistency.

Emulsification, on the other hand, is the go-to process when two immiscible liquids (such as oil and water) need to be combined into a stable emulsion. This is particularly useful in food processing, cosmetics, and pharmaceutical applications where emulsions are key ingredients in the product formulation.

Food Industry: Both homogenization and emulsification are extensively used in the production of processed foods. For example, homogenization is used in milk processing to break down fat molecules, while emulsification is used to create stable dressings and mayonnaise.

Pharmaceuticals: In pharmaceuticals, homogenization ensures that active ingredients are evenly distributed throughout a solution, while emulsification is crucial for creating topical creams and ointments.

Cosmetics: Emulsification plays a vital role in the production of skincare and haircare products, where different ingredients need to be blended into stable formulations. Homogenization ensures that the active ingredients in cosmetic products are evenly distributed.

In summary, homogenization and emulsification are two distinct processes that serve different purposes in various industries. While both aim to improve the consistency and stability of products, homogenization focuses on creating a uniform particle size within a single phase, and emulsification deals with creating stable mixtures of two immiscible liquids. Understanding the differences between these two processes is essential for selecting the right method for your product formulation needs.